A Comprehensive Overview to the Plastic Shot Molding Innovation

Plastic injection molding stands as a foundation of modern-day production, offering unmatched effectiveness and accuracy in the production of complex plastic elements. As the landscape of manufacturing progresses, understanding the future trajectory of shot molding comes to be significantly imperative.

Review of Plastic Shot Molding

Plastic shot molding is a widely made use of production procedure that enables the efficient production of complex plastic parts with high precision. This modern technology has become a cornerstone in various industries, including automotive, consumer items, and electronic devices, owing to its capacity to generate big amounts of parts rapidly and cost-effectively.

The procedure entails melting plastic granules and infusing the molten material into a pre-designed mold. Once cooled down, the mold and mildew is removed to disclose the finished part, identified by its complex information and uniformity. The flexibility of materials used in plastic shot molding, varying from thermoplastics to thermosetting polymers, enables producers to tailor items to satisfy particular requirements, such as resistance, stamina, and flexibility to heat or chemicals.

In addition, the effectiveness of this technique reduces waste and decreases production costs, making it an eye-catching choice for businesses aiming to optimize their production processes. As innovation advancements, technologies such as multi-material injection molding and the combination of automation continue to boost the capabilities of plastic shot molding, enabling the production of increasingly innovative items that satisfy the needs of modern markets.

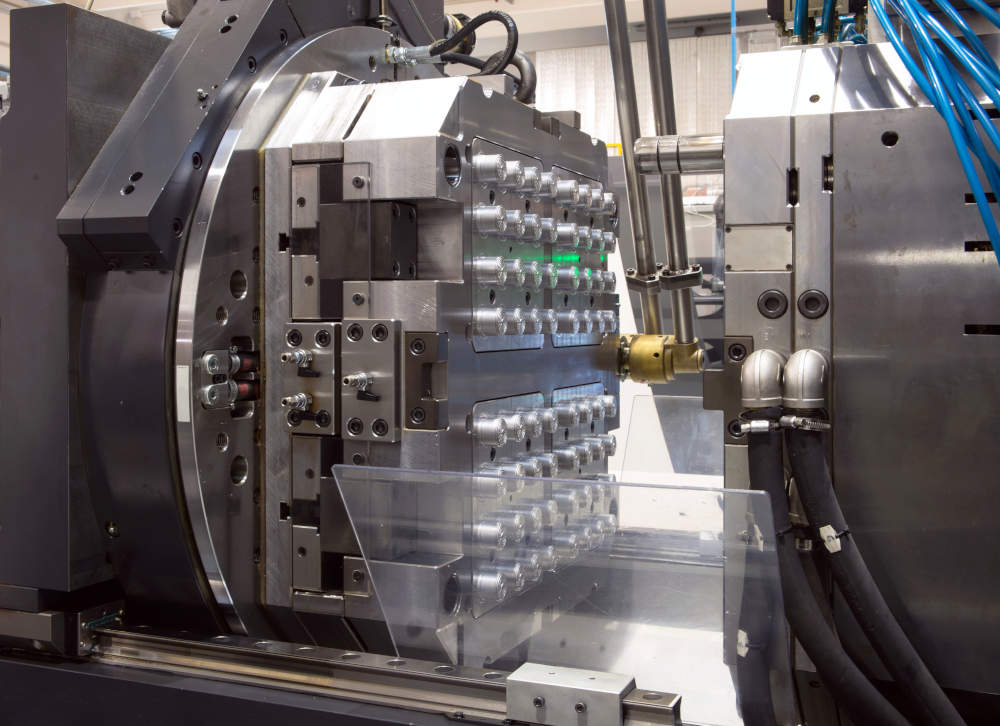

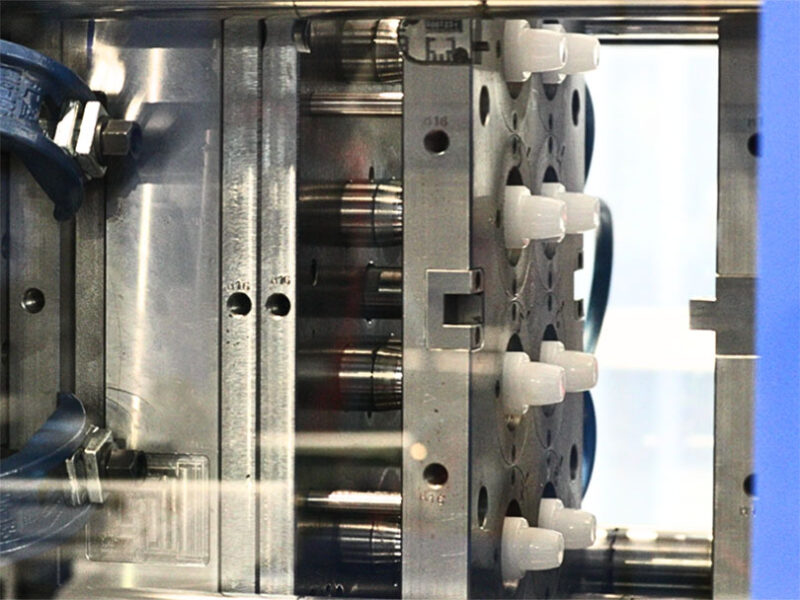

The Shot Molding Process

Injection molding is an innovative manufacturing technique that entails several important steps to transform raw plastic products right into finished products. The procedure starts with the preparation of plastic pellets, which are fed right into a warmed barrel. Here, the pellets are melted and homogenized to attain a consistent viscosity.

As soon as properly warmed, the liquified plastic is infused into a specifically engineered mold under high pressure. This action is crucial, as it enables the product to load every cavity of the mold, making sure the last item accurately shows the desired design. The injection time need to be meticulously controlled to stop flaws and make certain effective product usage.

After the mold and mildew is loaded, it undertakes a cooling phase, where the plastic solidifies into its last shape. This cooling process can vary in duration depending on the thickness and complexity of the part. When cooled, the mold opens, and the completed product is ejected.

Key Advantages of This Modern Technology

One of one of the most substantial benefits of shot molding modern technology depends on its ability to generate high volumes of accurate and constant parts with minimal waste. This efficiency stems from the automated nature of the procedure, which significantly lowers manual work and the possibility for human error. Consequently, producers can achieve a high level of repeatability in their result, making certain that each part meets rigorous top quality requirements.

Another trick advantage is the adaptability of materials that can be made use of in injection molding. A wide array of thermoplastics and thermosetting polymers can be formed, enabling customized properties to match particular applications. The modern technology supports complex designs and complicated geometries, which can be challenging to accomplish with various other producing techniques.

Cost-effectiveness is additionally an essential benefit, particularly for huge production runs. The preliminary financial investment in molds might be high, but the long-lasting financial savings in material waste and labor make shot molding a financially feasible option. Injection molding enables for fast manufacturing cycles, enabling business to react swiftly to market demands and minimize lead times. These benefits strengthen websites shot molding's position as a favored production procedure across various markets.

Applications Throughout Industries

In the medical field, injection molding is vital for making high-grade, sterilized parts, consisting of syringes, medical instruments, and housings for medical tools. The capability to keep limited tolerances and produce intricate geometries makes it an optimal selection for these applications. The packaging industry advantages from shot molding by producing a vast range of containers, closures, and dispensers that are both affordable and efficient.

The toy sector depends greatly on shot molding to create vivid, resilient, and secure products that attract kids. The building market makes use of shot molding for producing numerous components, fittings, and components that contribute to both capability and layout. Generally, the wide array of applications demonstrates the essential duty of shot molding technology beforehand various industries.

Future Trends in Injection Molding

Accepting developments in modern technology, the future of shot molding is positioned for considerable improvement driven by innovations in products, automation, and lasting techniques. One of the most noteworthy trends is the development of bio-based and recycled polymers, which not only reduce dependence on fossil gas yet likewise reduce ecological influence. As makers progressively prioritize environmentally friendly solutions, these products are ending up being much more widespread in manufacturing.

Automation is another vital pattern shaping the sector. The integration of robotics and expert system right into the shot molding process enhances effectiveness, manufacturing, and accuracy rate. Smart factories furnished with IoT devices permit real-time surveillance and predictive maintenance, lowering downtime and optimizing functional procedures.

Additionally, the shift in the direction of customized and small-batch production is obtaining momentum. Advanced innovations such as 3D printing and additive production make it possible for rapid prototyping and the development of complicated geometries that were formerly unattainable. This shift allows business to react better to market needs and customer preferences.

Verdict

Finally, plastic injection molding innovation stands for a keystone of modern manufacturing, providing performance and convenience in producing complex parts across diverse markets. The in-depth exam of the shot molding procedure highlights its critical phases and advantages, while the click over here now exploration of applications underscores its widespread significance. Additionally, emerging trends, including sustainability and automation, indicate a promising future for this technology. Continued improvements are most likely to improve production capabilities and environmental factors to consider, forming the landscape of production.

Plastic injection molding stands as a foundation of contemporary manufacturing, offering unrivaled performance and accuracy in the production of facility plastic elements (Plastic Injection Molding). The versatility of materials used in plastic shot molding, ranging from thermoplastics to thermosetting polymers, permits makers to tailor items to meet details requirements, such as toughness, versatility, and resistance to warmth or chemicals

Injection molding is an innovative manufacturing method that involves a number of critical steps to change raw plastic products into ended up products.The adaptability and efficiency of injection molding modern technology have led to its widespread fostering throughout various markets.In conclusion, plastic injection molding innovation stands for a cornerstone of i was reading this contemporary manufacturing, supplying efficiency and adaptability in generating complex parts throughout varied sectors.